How does Foamboard compare to Sintra Board | Pros and Cons to Both

Sintra Board vs Foam Board

What do malls, sidewalks and science fairs have in common? If you guessed signage, you got it right. Signages are everywhere you turn, they basically work as a GPS, telling you where to turn and where to get what you’re looking for without getting lost in a mall maze.

As popular as signs are, only a few people care to delve deep into what they are made of. Although not completely necessary, its sometimes best to know, especially if you’re thinking of running a signage business. Sintra boards and foam boards are quite popular in the signage business, and we’re here to tell you why.

Sintra boards

PVC board or Sintra board as it is commonly known as is a registered PVC board that has been used in signage businesses for more than 20 years. The process of printing on Sintra is the same as printing on acrylic or metal.

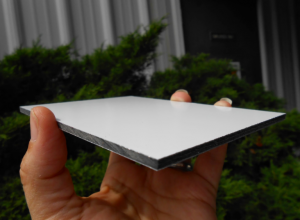

Sintra is the brand name for the high-quality PVC board, that is specifically made of moderately expanded closed-cell polyvinyl chloride, better known as PVC, in a homogenous sheet. The board is made from a lightweight material with a low gloss matte finish.

It is incredibly durable, which is especially why it is used for advertising, photo-mounting screen printing, and more importantly outdoor use. Other signage options are usually compared to Sintra, thanks to its high quality and common use.

Outdoor and Indoor use

Sintra PVC sheets are sometimes called sentra plastic sheets. They are resistant to dents, cuts, and scrapes, allowing you to leave your board outside for long periods under the scalding sun. Because Sintra is unaffected by the elements, it retains its appearance, looking new and polished over a long period of time.

These boards are everywhere and to prove this point, take a quick walk around your neighborhood and look out for real estate signages. They are also used in trade shows, like photo booth props, local kiosk signs, human-held outdoor signs, and many more.

If you need a board that can face the outside elements, then Sintra is the most ideal. Sintra boards can last for as long as 10 years if used strictly indoors.

Also, the lifespan depends on the quality of the material and how well you take care of it. Under extreme climate conditions, the boards can rapidly begin to show signs of aging.

Printing Options for Sintra Board

- Double-sided printing

- Custom cut Sintra boards

- Die cut/punch

- Lamination

- High gloss finish

Sintra Board Thickness

Sintra boards are typically about 1/4” or 1/8” thick, which is approximately 6mm and 3mm respectively.

Pros of Sintra board Printing

- Sintra board is easy to cut and can be customized into any shape or size.

- The board is heat formable ad chemical resistant

- It is resistant to dents and scratches

- It is more durable and stronger than foamboard

- Sintra boards are not affected by UV rays and can resist moisture.

Foamboard

Since 1957, foamboards crept into our lives and now we see them everywhere. From architectural students using it to build model building designs and structures to its use as a picture frame, foam boards are extremely versatile. Foamboards are quite like cardboard because of similar construction.

Foam boards also commonly referred to as foam core, is a display and printing material that consists of a dense foam core sandwiched between two sheets of matte paper. Foamboard is made from polystyrene, which is one of the most popular types of plastic that is also used to make Styrofoam.

Thanks to the polystyrene core of foam board that is 95-98% air, foam core boards are incredibly lightweight.

Outdoor and Indoor use

Unlike the admirable Sintra, foamboards do not hold too well with sunlight or moisture. They cannot be kept under the sun or exposed to moisture for prolonged hours. it is preferable to use foamboards for temporary outdoor display, otherwise, they tend to get warped, discolored, and disintegrated when exposed to the outside elements.

Foam board is also quite acidic, so avoid mounting archival materials on it because the chemical composition of the plastic will degrade the artifact over time. Lastly, foamboards are known to be fragile, easily dented by a little fall and can be snapped over your knee or punctured with a fingernail. So as much as possible take good care of your foamboards.

Printing Options for Foamboard

It is recommended to have your foamboard poster professionally printed directly onto the foamboard and not pasting a paper cut-out onto it. By doing so, the finished product will come out sleeker and this also reduces the chances of separation and bubbles that happen when you paste paper onto a board.

There’s a bunch of custom printing options, especially when you order from custom printers. The three most popular ones are double-sided foam core printing, laminated foam board prints, and heavy-duty poster board.

- Double sided foam core printing: you can either choose single-sided printing or double-sided foam core (foamboard) printing for an additional cost. Double sided prints are popular in most stores, where you can see the print from both directions while hanging from the ceiling. It is also a money-saver when doing presentations.

- Laminated foam board prints: To prolong the lifespan of your foamboard, consider laminating it. Not only would your print last long, but it will also give it a more polished finish. Although this comes at an added cost, it will definitely last longer.

- Heavy duty poster board: You can upgrade from the standard 3/16” foamboard material to ½” foamboard.

Foamboard Board Thickness

In comparing Foamboard vs Sintra board, the former is firm as cardboard and a little harder. They are generally 2mm and 5mm thick, which is approximately 1/8” and 3/16” respectively. One of the most common sizes of foamboard is 20” x 30”, however other sizes are available that are as large as 30 x 40 and as small as 12 x 18.

Pros of Foamboard

Foamboard is incredibly sturdy and rigid. It lies flat on its own, lies flat on its own, stay straight when propped up or hung and hardly bends or curls unless thrown under the sun. foamboards, much like Sintra, is lightweight, allowing you to easily move them from one place to another.

If you’re looking to reduce cost, foamboards are your best bet. It is affordable and one of the lest expensive printing and display materials on the market.

You also get a bunch of finishing options. You can laminate or frame your foamboard or finish it with a glossy, matte or textured finish.

So, to Print on Sintra board or Print on Foamboard?

Sintra board printing is a little bit more expensive than foamboards. Foamboards are on the ultra-light side while Sintra board is not as light. Foamboard has a paper exterior while Sintra board has a PVC exterior. One of the major differences between the two is that Sintra boards can be used outside, unfazed by the elements, on the other hand, foamboards need to be kept indoors and can only be used outside temporarily.

In terms of finish options, Sintra board has a matte finish, lamination, custom cut, die cut and double-sided print and can last for up to 10 years while foamboard has double sided, lamination and heavy duty. So, if you’re in need of an outdoor or indoor print both are good options.

Leave A Reply